OhmSpace: Revolutionising satellite propulsion with high-performance technology

OhmSpace is addressing one of the most pressing challenges in space: delivering fast, efficient, and sustainable satellite propulsion systems.

Founded by Dr Federico Romei, the company builds on a decade of innovative research in electric propulsion, which began during Federico’s time at the University of Southampton in 2013. His work evolved from Pulsed Plasma Thrusters to pioneering research on high-temperature resistojets under the mentorship of the late Dr Angelo Grubisic. This research culminated in the UKSA-funded STAR project and an EPSRC prototype programme, laying the technological foundation for OhmSpace.

After years of development, Federico was awarded the Royal Academy of Engineering Enterprise Fellowship in 2022. This allowed him to fully dedicate himself to the commercialisation of OhmSpace’s core technology. Following initial challenges with UK investors, he secured backing from Italian investors and co-founded OhmSpace in Rome, while retaining strong R&D ties in Southampton. In late 2022, Federico was joined by Matteo Careddu, whose automotive background added vital expertise in manufacturing and scale-up. Together, they raised their first major round of funding in late 2023.

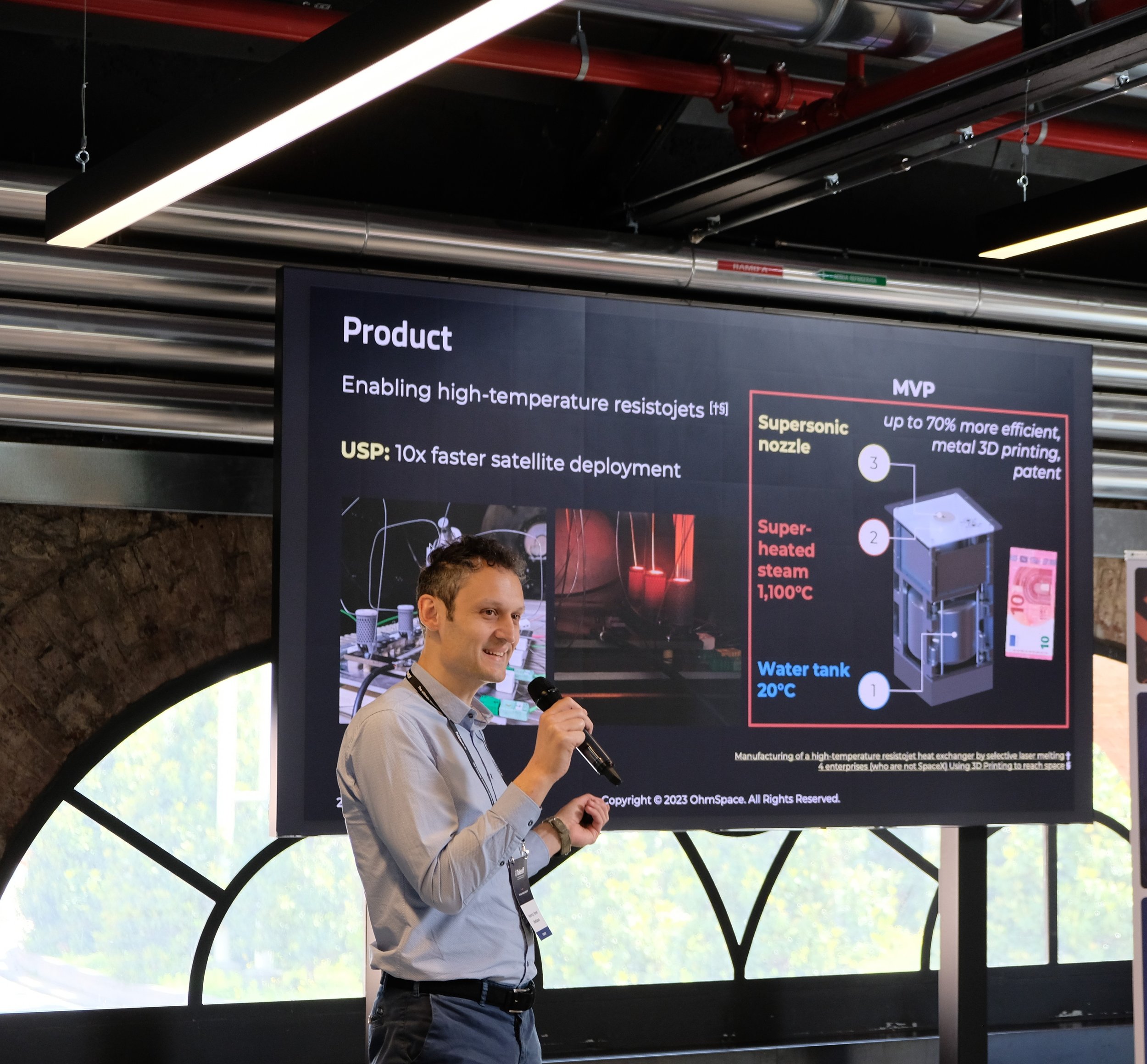

Founder and CEO, Federico Romei, pitching OhmSpace to investors.

Today, OhmSpace develops high-performance electric propulsion (EP) systems that outperform conventional EP in manoeuvrability and safety, while rivalling chemical systems in responsiveness. These systems enable critical satellite functions including orbit raising, collision avoidance, and end-of-life deorbiting. With growing space traffic and regulatory pressure on debris mitigation, the demand for propulsion solutions that are both fast and efficient is growing rapidly.

OhmSpace addresses this need with its patented electrothermal resistojet system. Unlike ion and plasma-based EP, which often sacrifices speed for efficiency, OhmSpace’s thrusters can deliver up to 100x faster manoeuvring. This is achieved through proprietary heater technology, capable of reaching over 2,000°C using advanced metal 3D printing (Selective Laser Melting). This results in up to 70% better propellant efficiency compared to conventional resistojets.

Their systems are also modular and scalable, compatible with satellite sizes ranging from 6U CubeSats to large geostationary platforms. The smallest configuration fits within just two CubeSat units and can complete multi-year missions using less than half a litre of water as propellant.

Senior Propulsion Engineer, Michael Magee, setting up the performance tests.

To meet growing demand, OhmSpace is scaling its production capabilities. While engineering model assembly and testing are currently carried out at the Southampton lab, a new manufacturing centre in Rome will bring the company's most critical processes in-house.

At the core of this plan is the establishment of advanced additive manufacturing for OhmSpace’s patented electric heaters and other key components. This in-house capability is a strategic move, enabling tighter quality control, accelerating development cycles, and setting the stage for productisation at scale. The aim is to deliver higher production volumes of plug-and-play electric propulsion systems tailored to the nanosatellite and small satellite markets.

Looking ahead, OhmSpace is preparing for a key milestone: the in-orbit demonstration of its technology, expected in the first half of next year This will validate the performance of its resistojet system in space and unlock commercial deployments and further investment.

Additionally, the company is developing a higher-power propulsion system for GEO applications through a new contract with the European Space Agency.

“By addressing the challenges of satellite propulsion with a safer, quicker, and more efficient solution, we are well placed to play a significant role in the future of space operations,” says Federico. “Our pioneering resistojet technology not only meets the demand for efficient, safe, and versatile propulsion systems but also contributes to the sustainable management of the increasingly crowded orbital environment.”